Electric generator rewinding is the process of replacing the coils or windings of the generator to restore its functionality. This process involves carefully removing the old coils, selecting the appropriate size and type of new ones, and then rewinding them onto the generator's core.

Electric generator rewinding is essential to ensure the generator continues to operate efficiently and produce the required power output. Without proper rewinding, the generator may experience reduced performance or even complete failure. We will explore the importance of electric generator rewinding, the steps involved in the process, and the benefits of hiring a professional to perform the rewinding task.

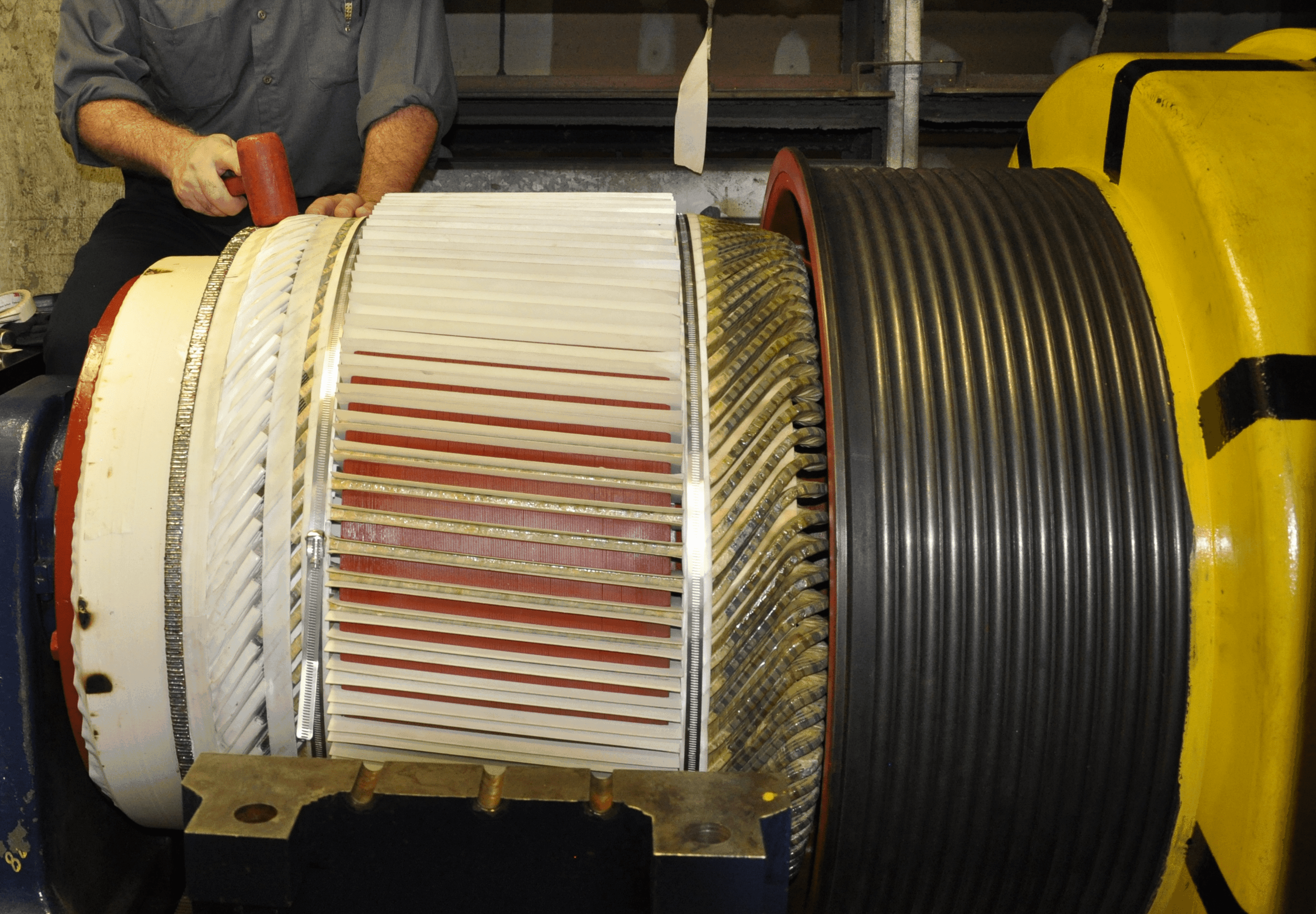

Credit: renown-electric.com

Process Of Electric Generator Rewinding

Electric generator rewinding is a crucial procedure that involves the repair and replacement of damaged windings within the generator. This process ensures the efficient functioning of the generator and extends its lifespan. The process of electric generator rewinding is divided into three main steps: evaluation and disassembly of the generator, removing existing winding, and the installation of new winding. Let's delve into each step to better understand the intricacies of this essential maintenance task.

Evaluation And Disassembly Of The Generator

The first step in the process of electric generator rewinding is the evaluation and disassembly of the generator. During this stage, a thorough assessment is conducted to determine the extent of damage to the windings and identify any other underlying issues. This evaluation involves carefully inspecting the coils, connections, and insulation of the windings to pinpoint any signs of wear, overheating, or short circuits.

After the evaluation, the generator is meticulously disassembled to gain access to the windings. This typically requires removing the rotor and stator, and sometimes even dismantling the entire generator to ensure a comprehensive examination. It is during this disassembly process that technicians also take note of the generator's specifications, such as the number of turns and wire gauge of the existing windings, to ensure accuracy in the rewinding process.

Removing Existing Winding

Once the generator has been thoroughly evaluated and disassembled, the next step in the rewinding process is the removal of the existing winding. This is a delicate task that requires the utmost care and precision to avoid any further damage to the generator components. Technicians carefully disconnect and remove the old windings, taking note of their arrangement and connections for reference during the installation of new winding.

The removal of the existing winding also involves checking the condition of the core laminations and insulation materials. If any damage or deterioration is detected, these components are repaired or replaced to ensure optimal performance and reliability of the rewound generator.

Installation Of New Winding, Ensuring

After successfully removing the existing winding, the final step in the electric generator rewinding process is the installation of new winding. This step requires skilled expertise and attention to detail to ensure the windings are correctly positioned and securely connected. The number of turns, wire gauge, and connections must match the original specifications to ensure proper electricity flow and avoid any potential damage or malfunctions.

During the installation process, technicians carefully wind the new coils around the core, making sure to maintain the desired tension to prevent sagging or loose windings. The connections between the coils and other components are meticulously secured, and the insulation materials are applied to protect the windings and prevent any electrical shorts or arcing.

Once the new winding is installed and all necessary connections are made, the generator is reassembled and tested to ensure its proper functioning. The rewound generator is then ready to resume its vital role in generating electricity efficiently and reliably.

Credit: www.emccltd.ca

Benefits And Challenges Of Electric Generator Rewinding

Electric generator rewinding is a critical maintenance procedure that can significantly extend the lifespan and improve the performance of your generator. By rewinding the coils and replacing worn-out components, you can ensure that your generator operates at its optimal efficiency. This process offers several benefits and cost savings, but it also comes with potential risks and challenges that require careful consideration. In this article, we will explore the advantages of electric generator rewinding, along with the associated challenges and how to address them.

Extended Lifespan And Improved Performance

Rewinding an electric generator's coils can greatly enhance its lifespan and performance. Over time, generator coils may become worn, damaged, or develop faults, affecting their ability to generate electricity efficiently. Rewinding allows for the repair or replacement of these faulty coils, ensuring optimal performance and preventing potential breakdowns. Additionally, rewinding allows you to upgrade the generator's winding configuration, which can help improve its power output and efficiency. By utilizing modern winding techniques and materials, you can maximize the generator's lifespan while ensuring it continues to operate at peak performance.

Cost Savings

One of the significant advantages of electric generator rewinding is the cost savings it offers. Rewinding provides a cost-effective alternative to purchasing a new generator. By opting for rewinding, you can restore your existing generator to its original functionality, avoiding the need for a costly replacement. Not only does this approach save on the initial investment, but it also eliminates the expenses associated with installation, commissioning, and system integration. Furthermore, rewinding can be completed in a shorter timeframe compared to acquiring a new generator, reducing downtime and minimizing any potential revenue loss.

Potential Risks And Challenges

While electric generator rewinding offers numerous benefits, it is important to be aware of the potential risks and challenges associated with the process. Improper rewinding techniques or the use of substandard materials can result in a decrease in performance or even catastrophic generator failure. To mitigate these risks, it is crucial to hire a reputable and experienced professional rewinding service provider. They will ensure that the rewinding process follows industry standards and utilizes high-quality materials. Additionally, undertaking regular inspections and maintenance can help detect any early warning signs of potential issues, allowing for timely intervention and minimizing the risk of generator breakdowns.

In conclusion, electric generator rewinding is a viable solution to extend the lifespan and improve the performance of your generator. It offers cost savings compared to purchasing a new generator and allows for customization based on your specific requirements. However, to ensure successful rewinding, it is crucial to choose an experienced service provider and conduct regular maintenance. By doing so, you can harness the benefits of generator rewinding while minimizing potential risks and maximizing the effectiveness of your generator.

Credit: jenkinselectric.com

Frequently Asked Questions Of Electric Generator Rewinding

How Much Does It Cost To Rewind A Generator?

Rewinding a generator cost varies depending on the size and type of the generator. It can range from $500 to $5,000.

How Do You Rewind A Generator?

To rewind a generator, follow these steps carefully: 1. Disconnect the generator from the power source and any devices connected to it. 2. Remove the generator's housing cover. 3. Locate the rotor and stator windings inside. 4. Calculate the gauge and length of wire needed for the rewind.

5. Carefully remove the old windings and replace them with new ones, ensuring proper connections. 6. Reassemble the generator and test it before reconnecting to power.

Can A Generator Stator Be Repaired?

Yes, a generator stator can be repaired. Professional technicians can diagnose and fix issues with the stator, such as winding faults or insulation damage. Proper repair can restore the functionality and efficiency of the generator.

What Are The Windings In An Electric Generator?

The windings in an electric generator are coils of wire that are wound around an iron core. These windings are the crucial parts that generate the electric current when the generator is in operation.

Conclusion

To conclude, electric generator rewinding is a crucial process that ensures the continued functionality and longevity of these devices. By re-coating the windings, it allows for efficient energy conversion and prevents damage to the generator. Regular rewinding and maintenance are essential to avoid costly repairs or replacements.

The expertise of a professional in this field is highly recommended to guarantee optimal performance. Keep your generator in top shape with proper rewinding for uninterrupted power supply.